|

Many South African manufacturers’ efforts to expand into Africa have failed. Two mistakes – according to speakers on the line-up for the 2016 SAPICS conference for supply chain professionals – are applying familiar product-focused processes, and discounting the importance of working within the existing framework of local culture.

Think distribution first, manufacturing second “Focusing too much capital expenditure on the production and manufacturing side without enough investment in the outbound supply chain – warehousing and distribution – is probably the single biggest mistake that South African companies make when expanding into Africa,” says Carsten Schubert, Director (East Africa) at Transnova Africa. “South African businesses readily accept the status quo of logistics systems and processes already in place in the country targeted for expansion, rather than challenging them and looking for more efficient ways of getting the product to market,” says Schubert. It is a dangerous practice to decide to make do with existing warehousing facilities and distribution processes if they are not suited to requirements for expansions into that particular territory. Another related mistake is abdicating control of the internal supply chain to distributors, with too much reliance placed on the local distributor’s network. “It is important to have visibility and control over your end to end supply chain,” warns Schubert. “Interacting directly and managing the relationship with your new customer base when you are trying to establish a foothold in a new market is a key success factor.” Productive interaction with a new environment relies strongly on working to understand local culture and their capabilities, and respecting the historic lessons that inform existing processes. Become immersed in the new culture “Every step of a new process needed to be designed through the eyes of the local workforce and their capabilities,” advises Bryan Baylis, Associate Director of Supply Chain with US-based Merck & Co Inc. “When local supply chain owners completely understand the proposed solutions, only then can your team execute a sustainable process, which can successfully meet the needs of the organisation today and well into the future.” Baylis explains that, as an outsider in a new environment, success is realised through complete immersion of oneself into the local culture, clearly understanding any existing processes, and working together as a cohesive team to provide viable solutions. “While new environments present unique challenges when designing supply chain systems, there is a common need to create a flexible system that can quickly adjust to today’s global environment,” says Baylis. The key to the success of an expansion project seems to be dependent upon keeping solutions smart enough to be effective, but simple enough to be sustainable in the local environment. Carsten Schubert and Bryan Baylis will present their unique supply chain insights at the 38th Annual SAPICS conference and exhibition for supply chain professionals in Sun City from 12 to 14 June 2016. More information is available at conference.sapics.org

0 Comments

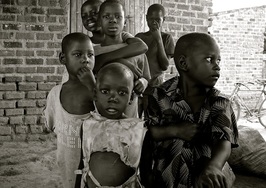

Africa’s child mortality rate is high, the highest in the world. Malnutrition in Sub-Saharan Africa sees one in eight children die before the age of five (UNICEF). “This, despite having the food to feed them”, says Hermann Haupt, CHEP Country GM Sub-Saharan Africa. “At 5% compared to the western world’s 60%, food waste in Africa (that by the consumer) isn’t the main problem,” stresses Haupt. “It is food loss – incidents during the early stages of the supply chain, from post-harvest and production to retail. We lose about 220 million tons of food this way annually but the food deficit needed to feed the hungry is only 45 million tons. We need to resolve only 20% of the losses to fix this crippling problem.” Haupt alerted supply chain professionals at the recent 37th annual SAPICS conference for supply chain professionals to the severity of the food crisis. CHEP is a division of supply chain logistics giant Brambles, which is actively looking at ways to remedy the situation. A vicious circle A consequence of malnutrition, explains Haupt, is stunting. 40% of the continent’s children are stunted – physically and mentally underdeveloped as a result of malnourishment, making them more susceptible to disease and less able to learn and ultimately work and develop themselves both from the persona and professional stand point. Haupt points out that “We need to work hard to reduce and ultimately eliminate malnutrition, thereby improving people’s lives whilst creating a value-adding economically active population”, he says. “Africa has five times fewer roads than the developed world,” Haupt says. “On top of that, congestion at seaports and delays at border posts makes for a challenging cold chain environment.” Harmonised effort by industry, government Haupt pinpoints 5 stages of food loss and the crucial Supply Chain Management (SCM) details often overlooked: Production “Yield in Africa is just 1.1 ton per hectare, but 3.2 tons in the rest of the world!” he says. “Even a small increase in yield can make a massive difference to the malnutrition problem. We need to find a way to transfer skills to Africa’s farmers.” Harvest processing Problems include timing, storage, and refrigeration methods Industry processing Taking consumer ready product and getting it to market. “Packaging is a major issue here,” Haupt explains. “When products are packaged in bulk or in containers that aren’t suitable, the packaging is easily crushed and the food wasted. Distribution and sales Forecasting is not accurate; resulting in oversupply and waste. Retailers focus only on displaying perfect looking food, rather than concentrating on whether the food is still nutritionally perfect. Waste Consumers buy too much and do not monitor sell-by dates. Haupt maintains that while some solutions, such as closer collaboration of Africa’s governments, building road/railways and processing facilities, are long-term; in the short term, the most sufficient supply chain is obviously one where the production facility is as close as possible to users. “Ultimately, we need a coordinated, collaborative effort if we are to make a difference here,” says Haupt, citing that the SCM industry is the place to start. “Correctly managing food supply chains can have an immediate result by overcoming obstacles in the getting of goods to those in desperate need,” ends Haupt. ENDS _______________________________________________________________________________________________________ MEDIA CONTACT: Cathlen Fourie, 012 644 2833, [email protected], www.atthatpoint.co.za For more information on SAPICS please visit: Website: www.sapics.org.za Twitter: @SAPICS01 LinkedIn: SAPICS group Facebook: OperationsManagement ABOUT SAPICS – your supply chain network SAPICS is a professional knowledge-based association that enables individuals and organisations to improve business performance. SAPICS builds operations management excellence in individuals and enterprises through superior education and training, internationally recognised certifications, comprehensive resources and a countrywide network of accomplished industry professionals. This network is ever expanding and now includes associates in other African countries.  Article by Kevin O’Marah, Chief Content Officer, SCM World I’ve been pitching Africa as a supply chain growth imperative for a while now. Our recent and bullish Africa report has had some pretty good reviews, making me confident that things are ready to happen. But one caveat keeps surfacing: the talent gap. What to do about finding, developing and managing people who are savvy about local conditions, but also sophisticated enough to navigate the waters at global headquarters? The talent problem in emerging markets is certainly not unique to Africa. We have consumer goods companies probing this question as it relates to entering China, hi-tech companies facing the issue in Latin America, and industrials wrestling with it in India. So much opportunity, but so few qualified people, and unfortunately expats don’t solve the problem since their skills mix is wrong and most are short-timers anyway. Here is one idea that may help – at least in Africa. South Africa leading the way This past week I spent two full days moderating a CEO roundtable with leaders from eight big South African companies. The event was noteworthy because it comprised top bosses drilling into how supply chain affects business value. It reached deeper into the business agenda of this group of leaders than anything I’ve seen in the US or Europe. Had this meeting been assembled by the World Economic Forum and held at Davos, I’d have been impressed, but not surprised. Instead it was arranged by SAPICS, the South African premier channel partner of APICS – a talent development organisation with headquarters in Chicago, USA, and a somewhat less-than-glamorous image. SAPICS is empowered to experiment with new ways of bringing business and supply chain together. The influence of these general managers on the SAPICS’ content and engagement strategies is direct as the education agenda is set by business leaders more than by consultants. Talent development through networking SAPICS hosts a conference every year in South Africa that draws hundreds of young, ambitious supply chain practitioners from all over the continent. I attended its 30th anniversary event a few years back and left with first-hand accounts of supply chains working in countries from Nigeria and Kenya to the Democratic Republic of the Congo and Zimbabwe. Hundreds of working supply chain professionals soaked up the education, handed out business cards and tried to get an edge in their careers. The vibe was less like emerging markets and more like Silicon Valley, unlike emerging markets events I’ve been part of in New York or London, where the audience was more worried about looking good than about learning. Emerging markets talent gap not unbridgeable The big takeaway is that talent in emerging markets – in this case, Africa – need not be something supply chain leaders have to face alone. SAPICS is a well-established association with events, members and affiliates all over the continent. It is young, but not green, and open to business input. It also has deep institutional support from APICS Supply Chain Council. ENDS MEDIA CONTACT: Juanita Vorster, 079 523 8374, [email protected] For more information on SAPICS please visit: Website: www.sapics.org.za Twitter: @SAPICS01 LinkedIn: SAPICS group Facebook: OperationsManagement |

Welcome to the SAPICS Newsroom. For media releases prior to August 2014, please click here.

Archives

January 2017

Categories

All

|

RSS Feed

RSS Feed